Advanced Water Treatment Solutions for Industrial Applications

Industrial water treatment has evolved dramatically over the past decade, with membrane technology leading the charge in revolutionizing how we approach water purification, recycling, and waste management. As industries face increasing pressure to reduce their environmental footprint while maintaining operational efficiency, advanced water treatment solutions have become not just beneficial, but essential.

Traditional water treatment methods, while effective in their time, often fell short of meeting the stringent requirements of modern industrial processes. The introduction of advanced membrane technologies has fundamentally changed this landscape, offering unprecedented levels of purification, efficiency, and sustainability.

Modern membrane systems can achieve up to 99.9% contaminant removal while reducing energy consumption by 30-50% compared to traditional methods.

The latest generation of membrane technologies offers several key advantages that make them ideal for industrial applications:

Advanced RO membranes now feature enhanced fouling resistance and improved flux rates, making them suitable for treating even the most challenging industrial wastewater streams. These systems can effectively remove dissolved salts, organic compounds, and trace contaminants.

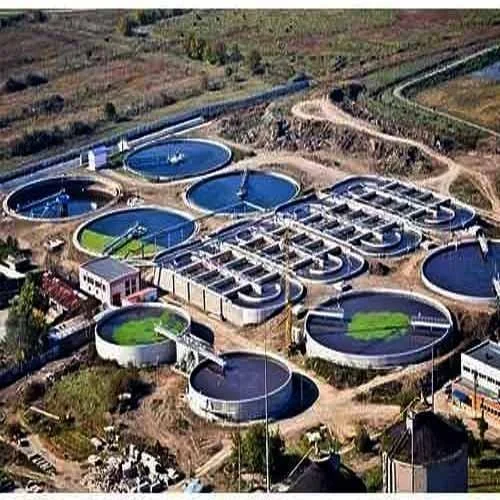

Modern RO systems in industrial water treatment facilities

UF membranes excel at removing suspended solids, bacteria, and macromolecules while allowing dissolved salts to pass through. This selective separation makes UF ideal for pre-treatment applications and process water recovery.

MBR systems combine biological treatment with membrane filtration, offering superior effluent quality in a compact footprint. These systems are particularly effective for treating high-strength industrial wastewater.

The versatility of modern membrane technology has led to successful implementations across various industries:

Major beverage manufacturers have achieved 95% water recovery rates using advanced membrane systems, significantly reducing freshwater consumption and wastewater discharge.

Pharmaceutical companies utilize ultra-pure water systems with multiple membrane stages to meet stringent quality requirements for drug manufacturing.

Chemical plants use specialized membranes to recover valuable products from waste streams, turning environmental liabilities into revenue sources.

Semiconductor manufacturers rely on advanced membrane technology to produce ultra-pure water essential for chip fabrication processes.

The adoption of advanced water treatment technologies delivers significant benefits across multiple dimensions:

A major automotive manufacturer reduced water consumption by 40% and achieved zero liquid discharge through the implementation of a comprehensive membrane-based water treatment system.

The future of industrial water treatment is being shaped by several emerging trends:

IoT sensors and AI-driven analytics are enabling real-time monitoring and predictive maintenance, optimizing system performance and reducing operational costs.

Next-generation membrane materials, including graphene-based and biomimetic membranes, promise even higher performance and durability.

Water treatment systems are increasingly designed with circular economy principles, focusing on resource recovery and waste minimization.

Advanced water treatment solutions represent a paradigm shift in how industries approach water management. By embracing membrane technology and other innovative approaches, companies can achieve significant environmental and economic benefits while ensuring compliance with evolving regulations.

The key to success lies in selecting the right combination of technologies for specific applications and working with experienced partners who understand both the technical and business aspects of industrial water treatment.

Our team of experts can help you design and implement advanced water treatment solutions tailored to your specific industrial requirements.

Get Expert Consultation